Reusable Desiccant, Economical and Environmentally Friendly

When the desiccant absorbs moisture and reaches its saturation, the system will automatically start the regeneration mode, and the moisture in the desiccant will be discharged through hot air circulation. Thus, the desiccant can be reused for 1 year.

Hygroscopicity, the tendency to absorb moisture, is a great enemy of 3D printing. Even a small percentage of humidity will have a negative impact on the properties of most carbon fiber filaments, glass fiber filaments and other materials. Printing with wet filaments will not only lead to surface quality defects, but also destroy the material properties, which will lead to the inability to meet the requirements of the application end. The importance of proper storage and drying of materials is self-evident.

[Real shot] Printed model quality comparison chart

The mechanical properties of 3D printed parts depends heavily on the storage of filaments

Wet filament

Wet filament

Filament after being dried

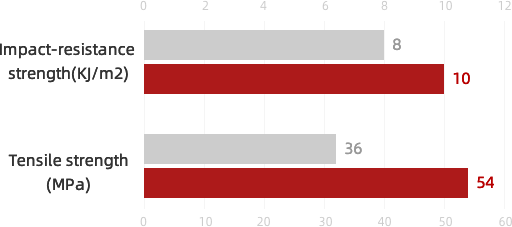

Printing PAHT after drying it:

The impact-resistance strength is increased by 100%;

The tensile strength is increased by 26%

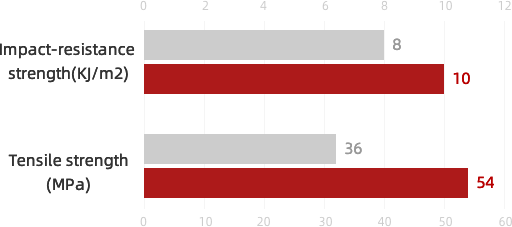

PA12-CF

Printing PA12-CF after drying it:

The impact-resistance strength is increased by 25%;

The tensile strength is increased by 50%

Annealing can obviously improve the strength of some 3D printed parts

Annealing treatment has a significant effect on PA-based materials, which can improve the strength of PA/PAHT/PA-CF while maintaining proper impact toughness.

Unannealed

Unannealed

Annealed

Annealed

Wet filament

Wet filament

Unannealed

Unannealed Annealed

Annealed